![]()

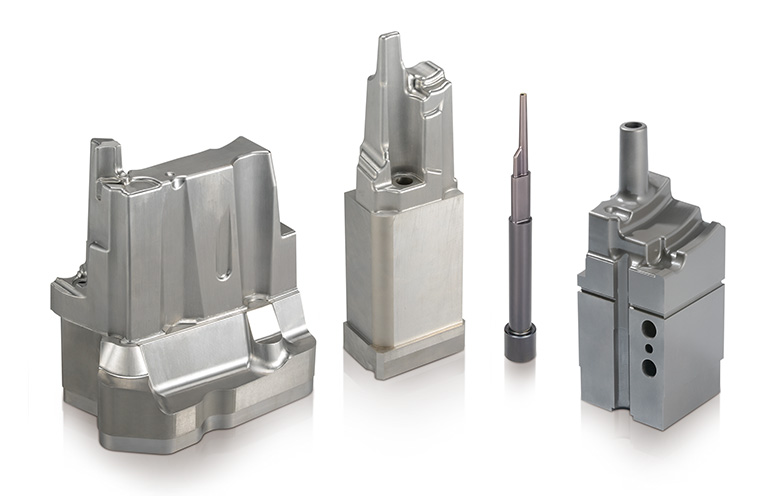

We have a long history of producing inserts for die-casting dies.

Recently, Aluminum die-casters are being tasked to reduce the weight of their castings with material saving inserts which are thin and have a long water hole.

We can produce an insert with a hole which is Ø3mm × L = 500mm, without difficulty.

We have all kind of TAP. (NPT, BSP M, UNF)

We have over 45 lathe and 25 machining centers at our three plants for these items.

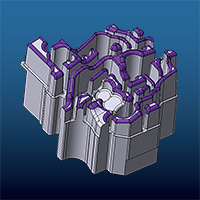

All die-casters and die-builders use different CAD system. But we would like to propose STEP and Parasolid, to transfer data. Because the data does not always translate accurately.

DYNAMO prefers to use STEP and Parasolid.

(Please contact us. We can handle CATIA and UG, Pro-E, Solidworks & Iges)

We prefer to use direct hard milling.

Minimum end mill size is Ø0.5mm and the machine is 20000 rpm/s. Where possible the insert is machined without EDM, removing the need for polishing the recast layer and re-tempering the part, increasing the shot life of the insert.

All inserts are checked on a 3 Axis CMM using the base 3D-Model supplied.

We choose at least 13 points on cavity area, and also at least 13 parts on the fit area.

We presently have 3 CNC CMM's all newer than 2009.